Batch and Continuous Distillation are two distinct methods of separating liquids based on their boiling points. They are tailored for different industrial needs depending on the volume and scale of operation.

Batch Distillation

• Features:

Applications:

Advantages:

Feed Solution Inlet → (A fixed volume of liquid mixture is

introduced into the distillation unit)

Heating Unit (Boiler/Reboiler) → (The liquid is heated to initiate evaporation)

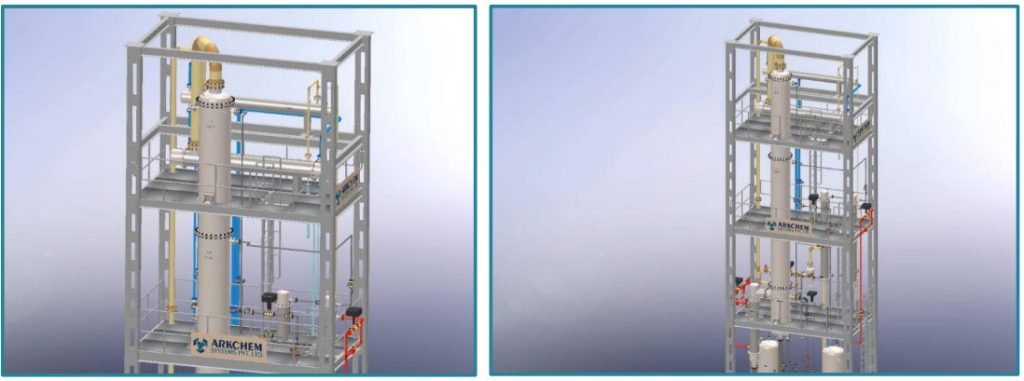

Distillation Column →

Fractionation Trays or Packing Material → (Enhances separation efficiency)

Vapor Rises → (Components separate based on boiling point differences)

Condenser Unit → (Cools vapor into liquid form for collection)

Distillate Collection Tanks → (Purified components are collected in separate

containers)

Bottoms Outlet → (Remaining concentrated liquid residue is removed)

Feed Tank & Pump (Controls the introduction of each batch into

the system)

Heating Unit (Boiler/Reboiler) (Provides heat for vaporization)

Distillation Column with Fractionation Trays/Packing (Optimizes separation process)

Condenser System (Cools vapor back into liquid for collection)

Vacuum System (Optional: Lowers boiling point for more efficient operation)

Final Collection Tanks (Stores purified fractions and residual components)