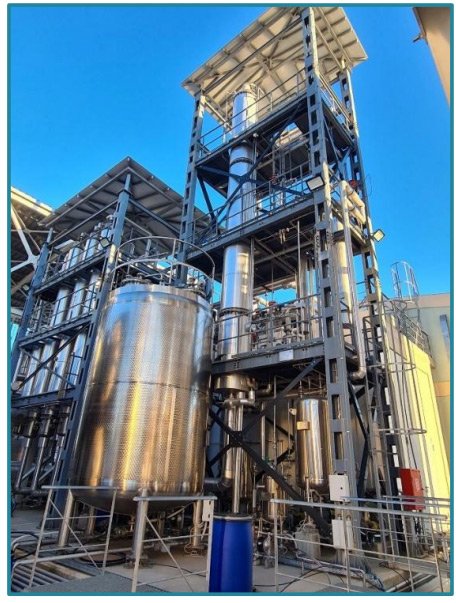

Fractional Distillation

Fractional distillation is an advanced method for separating liquid mixtures with components that have similar boiling points. It is commonly used in industries where high accuracy is required.

How It Works:

- Heating the Mixture: The liquid mixture is heated in a distillation flask, and the components

begin to vaporize. - Fractionating Column: The vapor rises through a fractionating column filled with packing

material or trays. This column helps separate components by repeatedly condensing and

vaporizing them based on their boiling points. - Condensation: The separated vapor reaches the condenser, where it is cooled and turned

back into liquid form. - Collection: Each component is collected separately in different containers as fractions.

Key Features:

- Precise Separation: Can separate components with close boiling points.

- Energy Efficient: Reuses heat during the separation process.

- Industrial Use: Suitable for large-scale operations like refining and chemical processing.

Applications:

- Oil Refining: Separates crude oil into fuels like gasoline, diesel, and kerosene.

- Chemical Industry: Purifies chemicals and solvents for industrial use.

- Alcohol Production: Separates alcohol from water in distilleries.

- Food Industry: Extracts Flavors, essential oils, and fragrances.

Material of Construction: SS 304 / SS 316 / MS / As per client needs

Process Flow for Distillation System

Feed Solution Inlet → (Liquid mixture enters the system for processing)

Heating Unit (Boiler/Reboiler) → (Liquid is heated, initiating vaporization)

Fractionating Column →

Packing Material or Fractionation Trays → (Enhances repeated condensation

and vaporization)

Component Separation → (Each substance separates based on boiling point

differences)

Condenser Unit → (Vapor is cooled and condensed back into liquid)

Distillate Collection Tanks → (Separated components are collected for further use)

Bottoms Outlet → (Remaining concentrated liquid residue is removed)

Key Equipment Involved

Feed Pump (Controls liquid entry into the system)

Heating Unit (Boiler/Reboiler) (Provides heat for vaporization)

Fractionating Column (Enhances efficiency through multiple condensation cycles)

Packing Material or Trays (Improves separation precision)

Condenser Unit (Recovers vapor by cooling it into liquid)

Vacuum System (Optional: Lowers boiling point for energy-efficient operation)

Final Collection Tanks (Stores purified distillates and bottom residue)