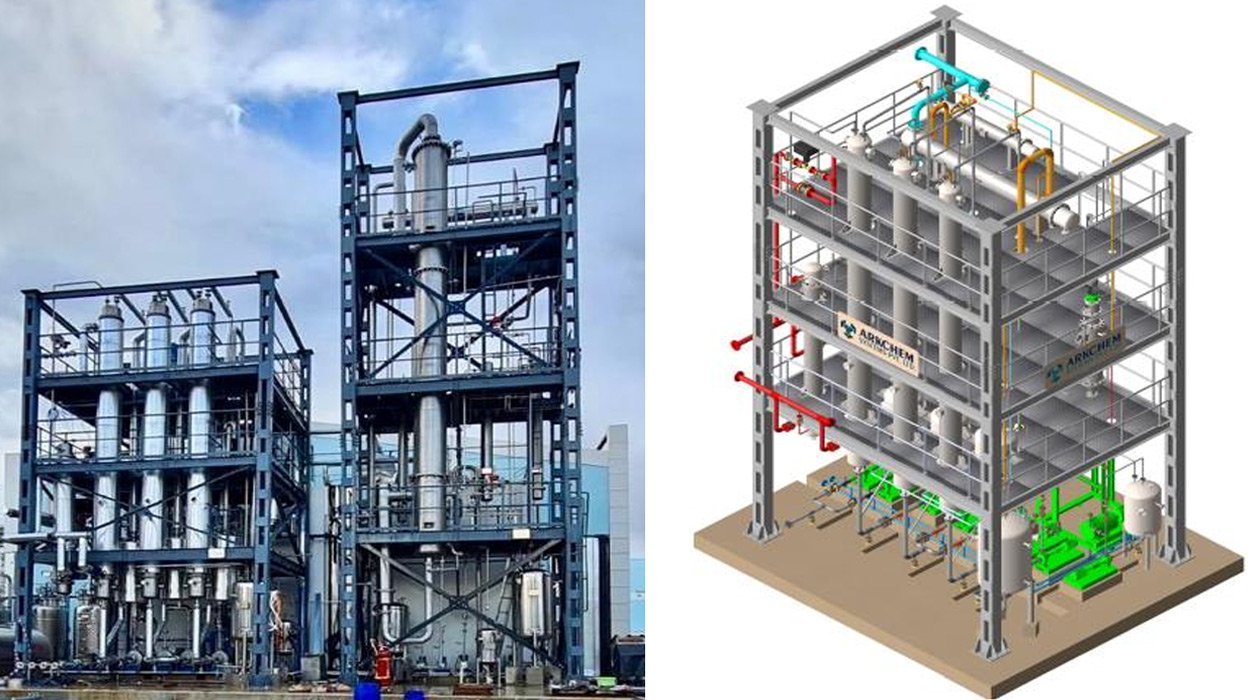

Multiple Effect Evaporation System

The Multiple Effect Evaporator (MEE) is a highly efficient system designed to reduce water content from solutions by using multiple stages of evaporation. This system maximizes energy efficiency by reusing the vapor generated in one stage as the heating medium for the next, making it an ideal solution for industries aiming to reduce energy costs and waste.

How It Works:

- Feeding the Liquid: The liquid to be evaporated is introduced into the system.

- Heat Application: In the first stage, heat turns part of the liquid into vapor.

- Reusing Heat: The vapor produced is used to heat the next stage, reducing energy use.

- Concentration: The liquid gets thicker as water is removed stage by stage.

- Vapor Collection: The water vapor is collected, condensed, and can often be reused.

Applications:

- Chemical Industry: Reducing water from chemical solutions for further use.

- Food Production: Making concentrated products like juices or milk.

- Textiles: Treating wastewater from dyeing processes.

- Effluent Treatment: Removing water from industrial waste to reduce disposal.

Benefits:

- Energy Saving: Uses less energy by recycling heat between stages.

- Cost-Effective: Cuts down on operational costs.

- Eco-Friendly: Reduces liquid waste and promotes water reuse.

- Customizable: Can be adapted to meet the needs of different industries.

- Reliable Performance: Works well even for heat-sensitive materials.

Why Choose Our MEE System?

- Advanced Technology: Precision-engineered to ensure reliability and performance.

- Custom Design: Tailored to your industry’s specific requirements.

- Sustainability Focused: Promotes resource conservation and eco-friendly practices.

- After-Sales Support: Includes training, spare parts availability, and maintenance plans.

Material of Construction: SS 304 / SS 316 / MS / As per client needs

Process Flow for Multiple Effect Evaporation (MEE) System

Feed Solution Inlet → (Liquid enters the system for evaporation)

First Effect Evaporator → (Initial heating turns part of the liquid into vapor using

steam)

Interconnecting Vapor Transfer → (Generated vapor is utilized to heat the next

stage) )

Second Effect Evaporator → (Further evaporation occurs using heat from the

previous stage)

Third Effect Evaporator → (Continued concentration process with efficient

energy use)

Final Effect Evaporator → (Maximum concentration achieved with minimized

energy consumption)

Vapor Collection & Condensation Unit → (Recovered vapor is condensed for

reuse)

Final Concentrated Liquid Outlet → (Stored for further processing or disposal)

Key Equipment Involved

Feed Pump (Ensures controlled liquid entry into the system)

Heat Exchanger / Steam Generator (Provides indirect heating for evaporation)

Multiple Effect Evaporator Chambers (Sequential stages of evaporation for

efficiency)

Vapor Separator (Removes entrained liquid droplets from the vapor)

Vacuum System (Optional: Reduces boiling point to optimize energy usage)

Condensation Unit (Recovers vapor and converts it back into liquid for reuse)

Final Collection Tank (Stores concentrated solution for further use)