Drying Systems

Dryers are advanced systems used to remove moisture from various materials, ensuring they achieve the desired level of dryness for further processing or packaging. These systems are designed to handle different materials efficiently while maintaining their quality and properties. Whether used in food processing, pharmaceuticals, or chemical industries, dryers are crucial for achieving high-quality output.

How It Works:

- Material Input: The wet or moist material is fed into the dryer system.

- Heating Process: The system applies controlled heat to the material, evaporating the moisture content. The heating method can vary depending on the type of dryer (hot air, steam, or infrared).

- Drying Mechanism: Advanced drying techniques like airflow circulation, agitation, or direct contact ensure uniform moisture removal across all parts of the material.

- Moisture Removal: The evaporated moisture is safely discharged or condensed, leaving the material completely dry.

- Collection: The dried product is collected for storage, packaging, or further processing.

Benefits:

- Efficient Moisture Removal: Ensures rapid and uniform drying of materials.

- Preservation of Quality: Maintains the integrity of heat-sensitive materials without degradation.

- Energy Saving: Optimized heating techniques reduce energy consumption during operation.

- Customizable Designs: Suitable for various industries and can be tailored to specific drying needs.

- Versatile Applications: Handles diverse materials, including powders, liquids, pastes, and granules.

- High Throughput: Designed for both small-scale and large-scale operations.

Applications:

- Food Industry: Drying fruits, vegetables, grains, spices, and dairy products for longer shelf life.

- Pharmaceuticals: Used for drying active ingredients, granules, and excipients.

- Chemical Industry: Removes moisture from chemical compounds, powders, and resins.

- Textiles: Prepares fabrics and materials by reducing water content.

- Environmental Engineering: Drying sludge and waste materials for safe disposal or reuse.

Why Choose Our Dryers?

- Advanced Technology: Incorporates cutting-edge heating and drying mechanisms for precise control.

- Eco-Friendly Design: Reduces energy usage and minimizes environmental impact.

- Customizable Solutions: Tailored systems to meet specific industrial requirements and materials.

- Durability: Built with high-grade materials for reliable long-term performance.

- After-Sales Support: Comprehensive training, spare parts availability, and maintenance services.

Material of Construction: SS 304 / SS 316 / MS / As per client needs

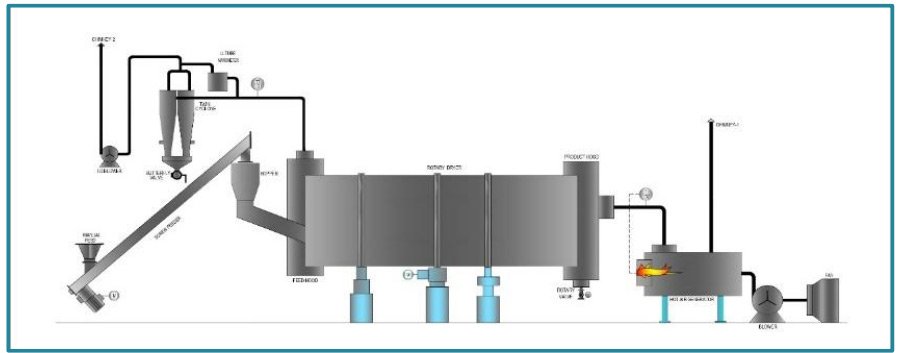

Process Flow for Drying System

Material Input → (Wet or moist material is introduced into the

drying system)

Heating Process → (Controlled heat is applied to evaporate moisture content)

Drying Mechanism → (Techniques such as airflow circulation, agitation, or direct

contact ensure uniform drying)

Moisture Removal System → (Evaporated moisture is discharged or condensed

efficiently)

Final Collection Unit → (Dried product is collected for storage, packaging, or

further processing)

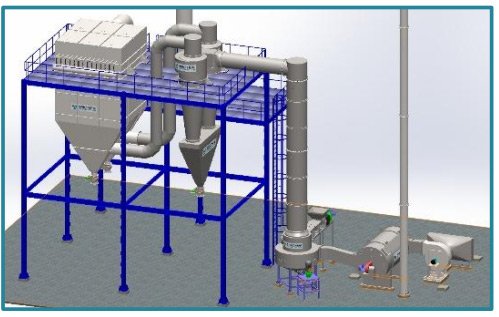

Key Equipment Involved

Feed Conveyor or Hopper (Regulates material input into the

drying system)

Heating Source (Hot air, steam, infrared, or microwave systems for controlled

drying)

Drying Chamber or Dryer Unit (Ensures uniform moisture removal using airflow

circulation or agitation)

Exhaust or Moisture Removal System (Safely discharges or condenses

evaporated moisture)

Vacuum System (Optional) (Enhances drying efficiency by lowering pressure)

Cooling Section (Optional) (Maintains product stability post-drying)

Final Collection Bins (Stores dried material for packaging or further processing)