Extraction Systems

Extraction systems are specialized setups designed to separate valuable components from raw materials. These systems are widely used in industries like pharmaceuticals, food, chemicals, and cosmetics to extract essential oils, active ingredients, or other compounds efficiently and effectively.

Types of Extraction Systems

- Extract aromatic oils from plants using methods like steam distillation or solvent extraction. Commonly used in perfumes, cosmetics, and aromatherapy.

- Use solvents to extract oils, fats, or active compounds from seeds, flowers, or other materials. Popular in food and pharmaceutical industries.

- Recover and recycle solvents used in extraction processes, reducing waste and improving cost-efficiency.

- Extract active ingredients from herbs for medicines, supplements, or cosmetics using water or alcohol-based methods.

- Recycle various solvents used across industries, promoting sustainability and reducing environmental impact.

How Do Extraction Systems Work?

- Material Preparation: The raw material is cleaned, crushed, or processed to prepare it for extraction.

- Extraction Process: The material is exposed to a solvent, steam, or other medium to separate the desired components.

- Separation: The extracted compound is separated from the solvent or medium.

- Purification: The compound is purified to remove impurities.

- Collection: The final product is collected for further use or packaging.

Features of Extraction Systems

- Efficient Separation: High precision in isolating desired compounds.

- Customizable Design: Tailored to specific industry needs.

- Energy Efficient: Optimized processes to reduce energy consumption.

- Closed Systems: Prevent contamination and ensure safety.

- Scalable: Suitable for small labs or large industrial operations.

Benefits

- High Yield: Maximizes the extraction of valuable components.

- Cost-Effective: Reduces waste and operational costs.

- Eco-Friendly: Promotes solvent recovery and minimizes environmental impact.

- Versatile: Handles a wide range of materials and applications.

- Safe: Operates in closed systems, ideal for sensitive or hazardous materials.

Applications

- Pharmaceuticals: Extracting active ingredients for medicines.

- Food Industry: Producing Flavors, essential oils, and nutritional supplements.

- Cosmetics: Extracting natural ingredients for skincare and beauty products.

- Chemicals: Processing dyes, pigments, and specialty chemicals.

Why Choose Our Extraction Systems?

- Advanced Technology: Incorporates the latest innovations for efficient and reliable extraction.

- Custom Solutions: Designed to meet your specific requirements.

- Durable and Reliable: Built with high-quality materials for long-term performance.

- Eco-Friendly Design: Reduces waste and promotes sustainability.

- Comprehensive Support: Includes training, maintenance, and after-sales services.

Process Flow for Extraction System

Material Preparation → (Raw material is cleaned, crushed, or processed to optimize extraction efficiency

Extraction Process → (Material is exposed to a solvent, steam, or supercritical fluid to separate desired components)

Separation Stage → (Extracted compound is separated from the solvent or medium using phase separation techniques)

Purification Stage → (Additional refining removes impurities and enhances compound purity)

Solvent Recovery System → (Solvent is recovered, purified, and reused in the process)

Final Collection & Packaging → (Purified compound is collected for further processing or commercial use)

Key Equipment Involved

Material Pre-Treatment Unit (Crushers, grinders, or homogenizers to process raw material)

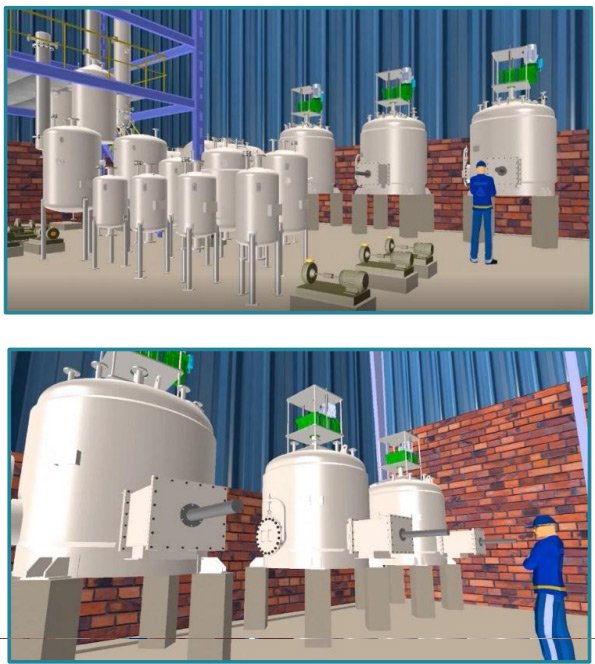

Extraction Vessel / Reactor (Uses solvent, steam, or supercritical fluids for component isolation)

Separation Unit (Decanters, centrifuges, or membrane filters for phase separation)

Purification System (Chromatography, distillation, or crystallization for refining)

Solvent Recovery System (Flash evaporators or distillation columns to recycle solvents)

Drying System (Vacuum dryers or spray dryers for moisture removal)

Final Collection & Storage Tanks (Safely stores purified extract for packaging or further processing)