Evaporation Systems

- Agitated Thin Film Evaporator / Wiped Film Evaporator

- Forced Circulation Evaporator

- Falling Film Evaporator

- Zero Liquid Discharge Multiple Effect

- Evaporation System

- Horizontal Thin Film Evaporator

- Rising Film Evaporator

Evaporation systems are industrial or scientific solutions designed to separate components in a liquid mixture through the process of evaporation. By heating the liquid, they convert it into vapor, leaving behind concentrated substances or extracting desired components. These systems are essential for industries like pharmaceuticals, food processing, chemical manufacturing, and environmental engineering.

Evaporation systems are commonly used for:

• Concentration: Reducing the liquid content to concentrate solutes (e.g., in sugar syrup production).

• Solvent Recovery: Extracting and reusing solvents from mixtures.

• Purification: Removing impurities from liquids to achieve higher purity.

• Desalination: Producing freshwater by evaporating seawater and condensing the vapor.

They often employ advanced technologies like multiple-effect evaporators or vacuum

systems to improve efficiency and handle various industrial needs.

How Evaporation Systems Work

Evaporation systems are designed to remove liquid from a solution or mixture by

transforming it into vapor. This process is achieved through controlled heating and phase separation, allowing industries to concentrate substances, recover solvents, or purify liquids effectively.

Here’s how the process works:

1. Heating: The liquid is heated in a controlled environment, causing it to evaporate into vapor. This can occur at standard or reduced pressure for efficiency.

2. Vapor Separation: The vapor is separated from the remaining concentrated mixture.

3. Condensation: The vapor is cooled and condensed back into liquid form, often for recovery or reuse.

4. Collection: The final concentrated solution is collected for further use or processing.

Evaporation systems are equipped with advanced mechanisms such as multi-effect

evaporators, vacuum technology, and automated controls, ensuring precise and energy efficient operation.

Evaporation systems are essential for generating precise concentrations of moist air, widely used in applications like testing, plant growth research, and aging processes. These systems rely on optimal control of pressure and temperature to ensure accuracy and efficiency.

• Precise Regulation: Liquid flow regulators and gas flow regulators ensure accurate control over moisture content and airflow.

• Efficient Vaporization: A temperature-regulated mixing and evaporation chamber ensures proper blending and vaporization of liquid into the carrier gas, with humidity adjustable from 5% to 95%.

• Low-Temperature Operation: The system uses a spiral heating tube to enable evaporation at low temperatures, enhancing energy efficiency.

• Consistent Precision: Any desired concentration can be achieved within seconds, maintaining accuracy and repeatability.

Key Components of Our Evaporation Systems:

1. Mass Flow Regulator – Controls and measures carrier gas flow.

2. Mass Flow Meter – Monitors liquid flow rates.

3. Temperature-Regulated Chamber – Ensures complete mixing and efficient evaporation.

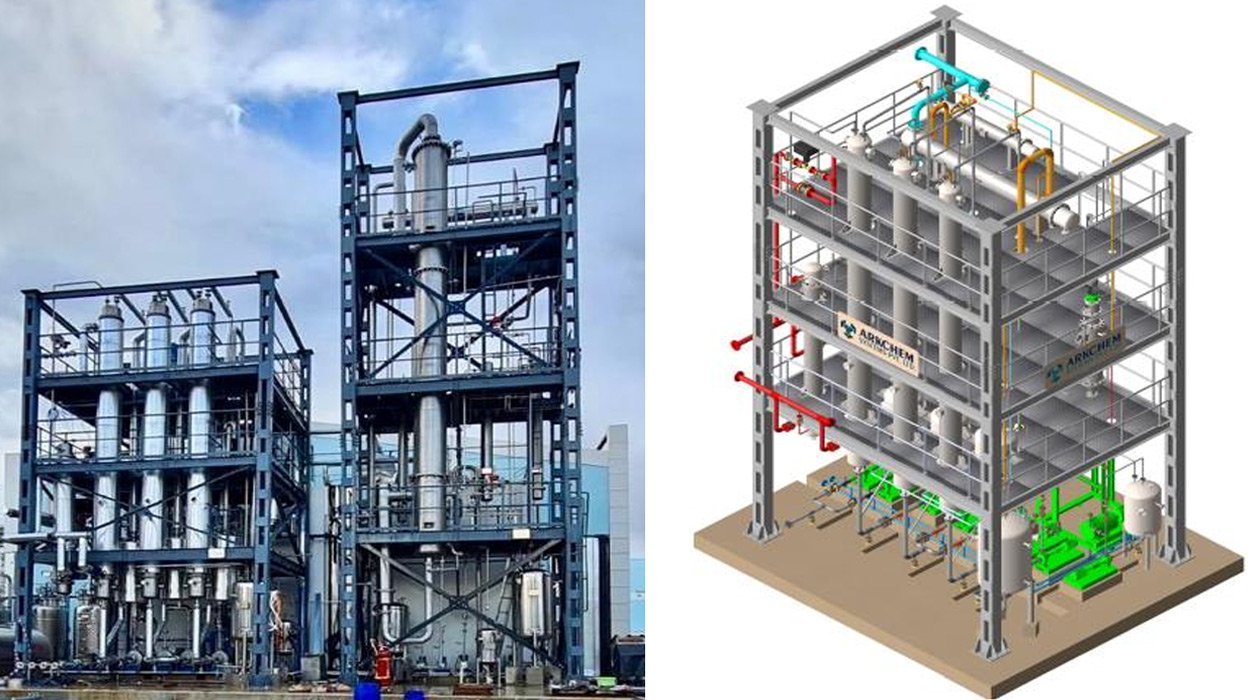

ARKCHEM’s evaporation systems simplify vapor generation, offering tailored solutions for industries while ensuring flexibility, efficiency, and compliance with technical requirements.

Used widely in industries like food processing, pharmaceuticals, and environmental

engineering, evaporation systems are essential for reducing costs, improving productivity, and delivering high-quality results.